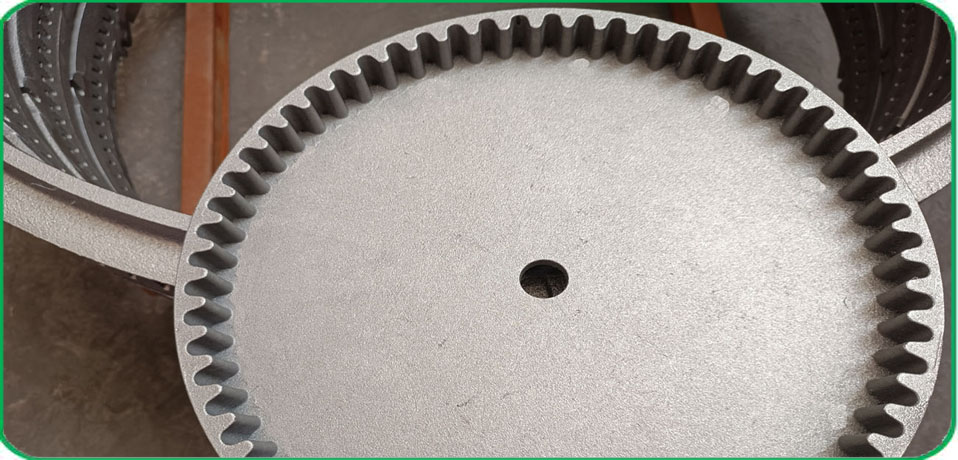

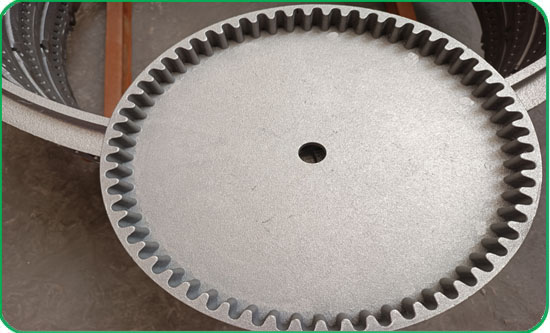

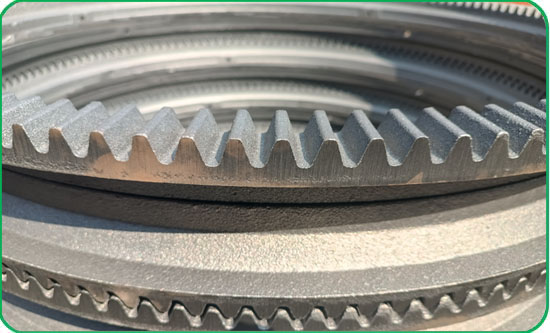

QEGM has 15+ years of custom ring gears manufacturing experience in concrete mixer industry. We have abundant experience and stong understanding of the whole production process detail, including the raw materials, moulding, melting temperature,hardness, deformation,grinding, gear width, gear flatness, packing and so on.

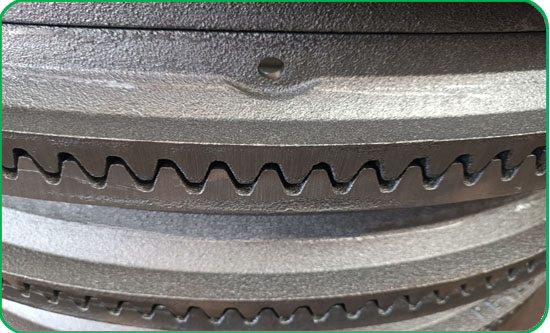

Common base material is grey iron or ductile iron for our ring gears, which are used widely as components on concrete mixer. They're produced by clay sand or precoated shell moulding process according to different ring gears' types.

As our automatic cold precoated shell moulding line set up, about 500pcs shells per day are produced by one machine(total 4 cold moulding machines we have), which support much to our competitive advange in market to guarantee our delivery and cost control.